Welcome to Qingdao Steel Building Co., Ltd.

Steel Structure Components – Blocks of Modern Steel Construction

02-02

2026

Steel Structure Components – Blocks of Modern Steel Construction

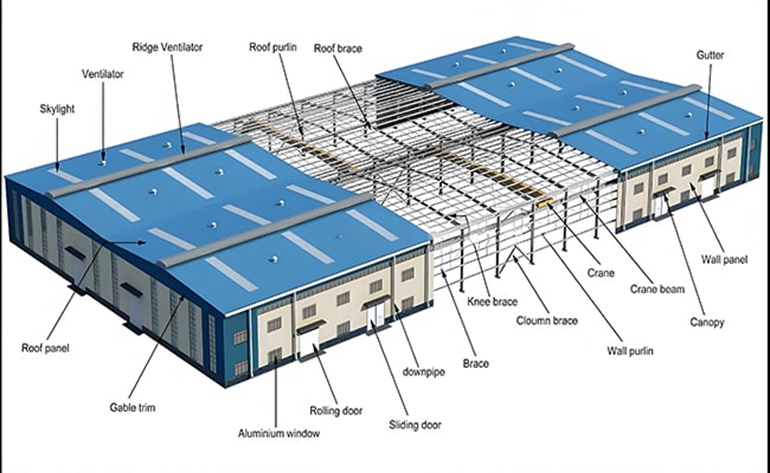

Steel structure components refer to the independent building elements that constitute an integrated steel building system. Each component is engineered to bear specific loads, resist environmental impacts, and act as the base for architectural finishing works. The overall performance of these components in combination dictates the safety, construction efficiency, and long-term durability of the entire steel structure.

1. Main Types of Steel Structure Components

Steel structure components are categorized by their functional roles, divided into four core types: primary load-bearing components, secondary supporting components, external cladding components, and connection components, each with distinct structural functions.

1.1 Primary Components

As the core load-bearing elements of the steel structure system, they bear the main vertical and horizontal loads of the building and transfer them to the foundation.

- Steel Columns: Vertical load-bearing members that transmit compressive loads from the roof, floors, and upper structural layers downward to the building foundation.

- Steel Beams: Horizontal load-bearing elements that carry the loads of floors and roofs, and transfer these loads to steel columns in a concentrated manner.

- Steel Frames: Assemblies of rigid or braced frames formed by the connection of steel columns and steel beams, providing the primary structural support for the entire building and resisting structural deformation caused by external loads.

1.2 Secondary Components

These components serve as auxiliary supports, connecting and reinforcing the primary frame structure, and ensuring the overall stability of the main load-bearing system.

- Purlins: Horizontal secondary members fixed to the roof frame, whose main function is to support the roof cladding sheets and distribute roof loads to the main roof frame.

- Girts: Horizontal secondary supports installed on wall steel columns, used to bear the weight of wall cladding and transmit wall loads to the wall columns.

- Bracing Systems: The key to resisting lateral loads (e.g., wind load, seismic load), common forms include X-bracing, knee bracing, and diagonal bracing. They stabilize the steel frame and prevent lateral deformation or collapse of the structure.

1.3 Cladding Components

Form the external enclosure of the steel structure building, responsible for weatherproofing, thermal insulation, sound insulation, and shaping the building’s external facade.

- Wall Panels: Usually made of steel plates or composite materials, they form the external wall of the building and play roles in windproofing, rainproofing, and thermal insulation.

- Roof Panels: Mostly galvanized steel panels or insulated composite panels, with core functions of weatherproofing (preventing rain, snow, and leakage) and improving the building’s thermal performance.

- Insulation Layers: Thermal and acoustic insulation materials laid under wall and roof panels, used to regulate the building’s internal temperature, reduce energy consumption, and improve acoustic comfort.

1.4 Connection Components

The "linkage" of the steel structure system, realizing the reliable connection and integration of all individual components, and ensuring the structural continuity and force transmission of the entire steel building.

- Bolts and Nuts: High-strength fasteners for flexible assembly of beams, columns, bracings, and other components, easy to install and maintain.

- Welded Joints: Permanent and rigid connection forms, critical for ensuring the continuous transmission of structural forces and improving the overall rigidity of the frame.

- Anchor Bolts: Embedded in the concrete foundation, they fix the steel frame to the foundation, preventing the entire steel structure from sliding or overturning under external loads.

2. Core Functions of Steel Structure Components

Each component undertakes a specific structural role, and their coordinated work forms a stable and stress-resistant steel structure system:

- Steel columns and steel beams: The core of load distribution, responsible for transmitting vertical dead loads (e.g., building self-weight) and live loads (e.g., personnel, equipment) and horizontal loads to the foundation;

- Purlins and girts: Secondary load transfer, distributing the loads of cladding components to the primary frame to avoid local stress concentration of the main structure;

- Bracing systems: The "stabilizer" of the structure, resisting lateral forces such as wind and earthquakes to ensure the lateral stability of the building;

- Cladding components: The "protective layer" of the building, isolating the external environment and improving the building’s thermal, acoustic, and weatherproof performance;

- Connection components: The "bridge" of force transmission, ensuring that all components form a unified force-bearing whole and realizing the smooth transmission of loads between different components.

3. Common Materials for Steel Structure Components

The selection of steel materials is determined by the building’s load requirements, usage environment, and regional engineering standards, with surface treatment to enhance corrosion resistance and durability:

3.1 Main Structural Steel Grades

- China’s mainstream grades: Q235 and Q355 structural steel (the most widely used, with balanced strength and cost performance);

- North American mainstream grades: ASTM A36 (ordinary carbon structural steel) anGr50 (high-strength low-alloy structural steel, for heavy load-bearing structures).

3.2 Special Environment Steel Materials

- Hot-dip galvanized steel: For general outdoor or humid environments, with basic corrosion protection;

- Stainless steel/weathering steel: For harsh environments (e.g., coastal areas with high salt spray, industrial areas with corrosive gas), with enhanced corrosion and durability performance.

3.3 Surface Treatment Processes

Painting, powder coating, and hot-dip galvanizing are the most common processes, which form a protective layer on the steel surface to prevent rust and corrosion, and extend the service life of components—especially important for outdoor, coastal, or humid engineering projects.

4. Significance of Precision and Quality in Component Fabrication

High-precision and high-quality fabrication is the prerequisite for the safe operation of steel structures:

- Structural safety: Poorly manufactured components (e.g., size deviation, unqualified welding) will lead to misalignment during assembly, joint failure, and even structural collapse under load;

- Construction efficiency: Precise components ensure smooth on-site assembly, reduce rework, and shorten the construction period;

- Cost control: Unqualified components increase the cost of rework, maintenance, and later reinforcement.

Adherence to international quality standards (e.g., ISO 9001 quality management system) and professional industry certifications (e.g., AISC American Institute of Steel Construction certification) is the core guarantee for the fabrication quality of steel structure components throughout the production process.

5. Application Scenarios of Steel Structure Components

Steel structure components are widely used in modern construction due to their advantages of high strength, light weight, prefabrication, and fast construction, covering multiple fields:

- Industrial buildings: Factories, logistics warehouses, production workshops (adapt to large spans and heavy load requirements);

- Commercial architecture: Shopping malls, office towers, high-rise buildings (facilitate modular construction and high-rise design);

- Public infrastructure: Airports, railway stations, sports arenas, exhibition centers (meet the demand for large space and flexible layout);

- Civil engineering structures: Bridges, viaducts, large-span culverts (with high load-bearing capacity and seismic performance);

- Prefabricated/modular buildings: Portable container houses, prefabricated residential buildings (conforms to the development trend of green and sustainable construction).

6. Conclusion

Steel structure components are the fundamental building blocks of modern architectural and structural engineering, and each type—from the primary load-bearing columns and beams to the intricate connection bolts and anchor bolts—plays an irreplaceable role in ensuring the structural safety, construction efficiency, and environmental resilience of buildings. The selection of high-quality steel materials, strict adherence to precision fabrication standards, and cooperation with experienced professional manufacturers not only guarantee the long-term structural performance of steel buildings but also create greater economic value and meet the development requirements of green and sustainable construction in the industry.