Welcome to Qingdao Steel Building Co., Ltd.

Corrosion Protection for Steel Buildings in Coastal Areas

12-15

2025

Corrosion Protection for Steel Buildings in Coastal Areas

Corrosion Protection for Steel Buildings in Coastal Areas: A System-Based Approach

Corrosion protection for steel buildings in coastal areas should be addressed as a system-level challenge. Coastal environments expose buildings to salt-laden air, high humidity, intense ultraviolet radiation, and frequent condensation cycles. These factors work together to accelerate corrosion far beyond what is typically observed inland.

While structural steel frames are often designed and protected according to recognized standards, the building envelope is usually the most exposed and vulnerable part. Roofing and wall systems receive direct salt deposition and solar exposure, while joints, laps, and fasteners create localized conditions that trap moisture and chlorides. As a result, corrosion often progresses faster in the envelope than in the main structure.

A durable coastal steel building—and especially steel buildings in coastal areas—requires a coordinated strategy covering structural protection, roofing materials, wall cladding systems, detailing, and maintenance planning.

Why Coastal Environments Accelerate Corrosion in Steel Buildings

Coastal corrosion is aggressive because multiple degradation mechanisms act simultaneously.

Salt aerosols carried by wind can travel several kilometers inland and settle on exposed surfaces. High humidity and nighttime temperature drops cause condensation on roofs and walls, creating repeated wet–dry cycles. Strong ultraviolet radiation degrades organic coatings over time, reducing flexibility and allowing moisture to penetrate. In port or industrial areas, airborne pollutants further intensify corrosion reactions.

These conditions affect not only steel frames but also roofing sheets, wall panels, fasteners, gutters, and accessories, making coastal corrosion a building-wide issue rather than a material-specific one.

Structural Steel Protection Strategies for Coastal Buildings

Structural steel remains the backbone of any steel building and must be adequately protected in coastal environments.

Hot-dip galvanizing is widely used for secondary steel members such as purlins, girts, bracing, stairs, and platforms. Zinc provides sacrificial protection and continues to protect steel even when minor mechanical damage occurs.

For primary structural members, high-performance coating systems are commonly applied. These typically include a zinc-rich primer, a high-build epoxy intermediate layer, and a durable topcoat such as polyurethane or polysiloxane. In severe coastal exposure zones, duplex systems that combine galvanizing with paint offer extended service life and reduced maintenance requirements.

However, even the most robust structural protection will not guarantee long-term building performance if the roofing and wall systems are poorly selected.

Why Roofing Systems Are the Most Critical Corrosion Component

In many coastal steel buildings, roofing systems experience corrosion-related failures long before the structural frame shows any signs of deterioration. Roof panels are continuously exposed to salt deposition, strong sunlight, wind-driven rain, and thermal movement. Seams, fasteners, and penetrations create additional vulnerability.

Once roof corrosion begins, it often leads to water ingress, insulation damage, increased interior humidity, and accelerated corrosion of secondary steel elements. For this reason, the selection of roofing material is one of the most important corrosion-related decisions in coastal projects.

Aluminum Roofing for Severe Coastal Environments

Aluminum roofing is recognized as one of the most corrosion-resistant solutions available for coastal steel buildings. Aluminum naturally forms a stable oxide layer that protects it from further corrosion, even in salt-rich atmospheres.

Its advantages include excellent resistance to marine corrosion, lightweight properties, and minimal long-term maintenance. Aluminum roofing is particularly suitable for logistics warehouses, port facilities, and industrial buildings located in high-salinity coastal zones.

The main limitations of aluminum roofing are its higher initial cost and greater thermal expansion compared to steel, which must be addressed in design. Nevertheless, for projects where durability and lifecycle cost are the primary concerns, aluminum roofing is often the preferred solution.

Aluminum-Zinc Coated Steel Panels (Al-Zn / Galvalume)

Aluminum-zinc coated steel panels provide a practical and widely adopted solution for coastal steel buildings. The Al-Zn coating combines aluminum’s barrier protection with zinc’s sacrificial protection, offering significantly better performance than conventional galvanized steel in marine environments.

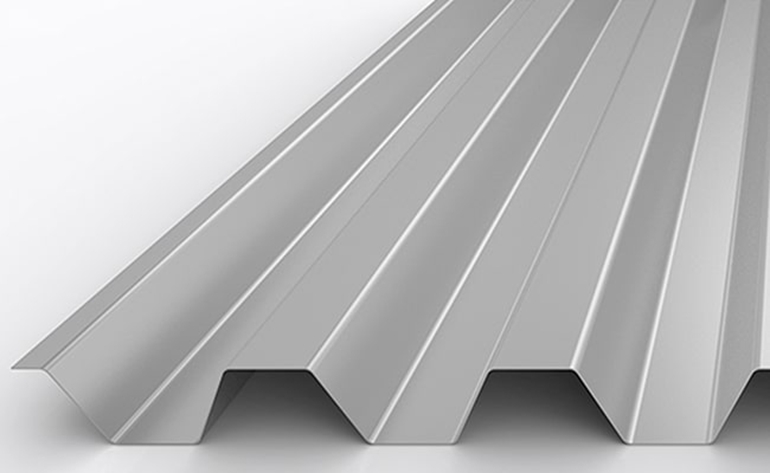

These panels exhibit slower corrosion rates, better resistance to salt spray, and longer service life near the sea. As a result, aluminum-zinc coated steel is commonly used for both roofing and wall cladding in coastal industrial and warehouse projects.

Wall Cladding Systems and Internal Condensation Risks

Wall cladding systems are often overlooked in corrosion planning, yet they play a crucial role in coastal steel buildings. Exterior walls are exposed to wind-driven salt spray, particularly on seaward façades, while interior wall surfaces may suffer from condensation caused by stored goods or industrial processes.

Selecting corrosion-resistant wall panels, incorporating proper vapor barriers, and ensuring adequate ventilation significantly reduce the risk of hidden corrosion and extend the building’s service life.

Fasteners, Accessories, and Detailing: Small Components, Big Impact

In coastal environments, corrosion frequently begins at fasteners, bolts, and accessories. If these elements are improperly specified, localized failures can spread rapidly and compromise surrounding materials.

Using galvanized steel or specially coated fasteners, avoiding incompatible metal contact, and designing details that prevent water accumulation are essential parts of a reliable corrosion protection strategy.

Design and Maintenance Considerations for Long-Term Performance

Effective corrosion protection is not limited to material selection. Good design practices—such as ensuring drainage, minimizing water traps, simplifying connections, and allowing inspection access—dramatically reduce corrosion risk.

Planned maintenance also plays a vital role. Regular inspections and timely localized repairs are far more cost-effective than large-scale rehabilitation after corrosion has progressed unchecked.

Conclusion: A Holistic View of Corrosion Protection for Coastal Steel Buildings

In coastal regions, corrosion protection must be approached holistically. Protecting only the steel frame is not sufficient. Roofing systems, wall cladding, fasteners, coatings, and detailing often determine whether a steel building performs reliably for decades or requires frequent and expensive repairs.

Effective corrosion protection for steel buildings integrates material selection, coating technology, architectural detailing, and maintenance planning into a unified strategy. When treated as a system rather than a standalone specification, steel buildings can achieve long service lives even in the most aggressive coastal environments.