Welcome to Qingdao Steel Building Co., Ltd.

Steel Poultry Shed Chicken House

Description

Light steel frame prefabricated modern chicken poultry farm shed, Steel structure broiler chicken farm shed,chicken farm building, chicken house,broiler house, poultry farm building

Product Information

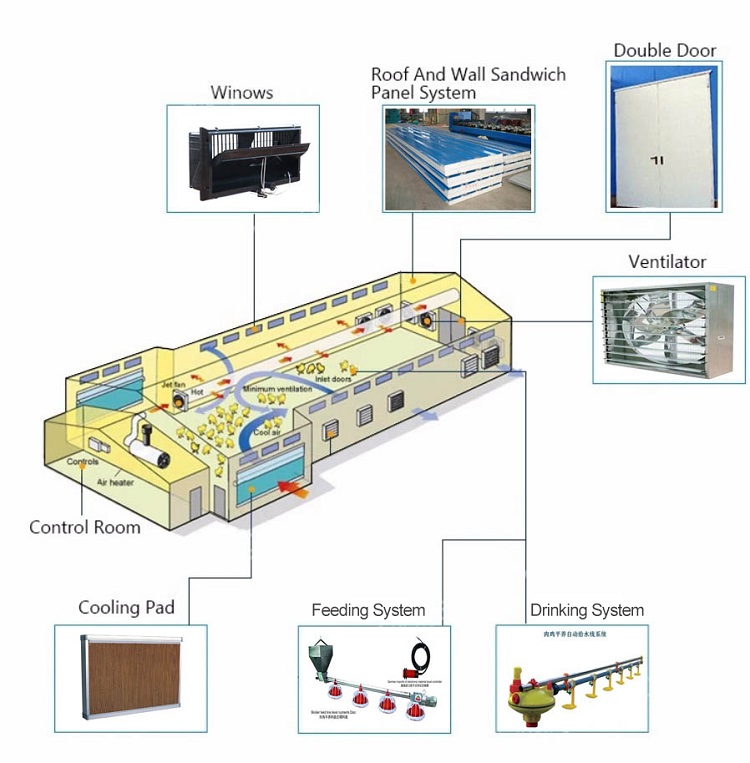

Poultry Shed is a kind of light steel structure with the main framework which is composed of main feeding system, chain feeding system, nipple drinking system, ventilation system, environmental control system, and spraying system. The wall is made with EPS, PU, fiber glass, or rock wool sandwich panel or steel mesh. The roof is made with one layer corrugated steel sheet or colored sandwich panels.

Building your poultry houses requires understanding of the specific, demanding conditions to ensure a trouble-free construction. This is exactly what We can offer you.As a manufacturer and constructor of buildings in cold-formed steel, we are constantly optimizing our building solutions to adapt to the requirements of your dynamic business.

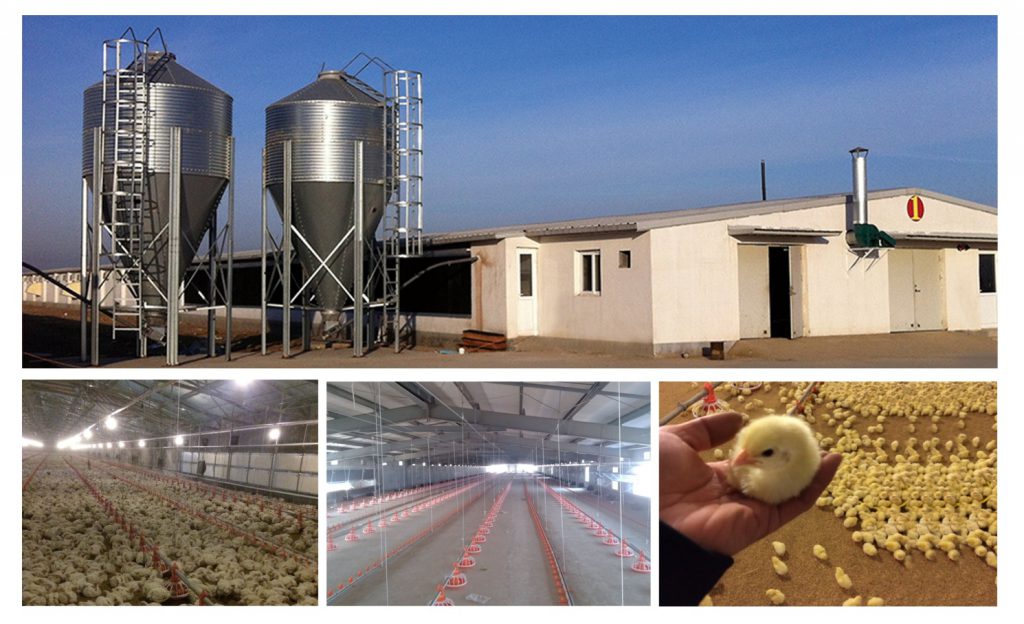

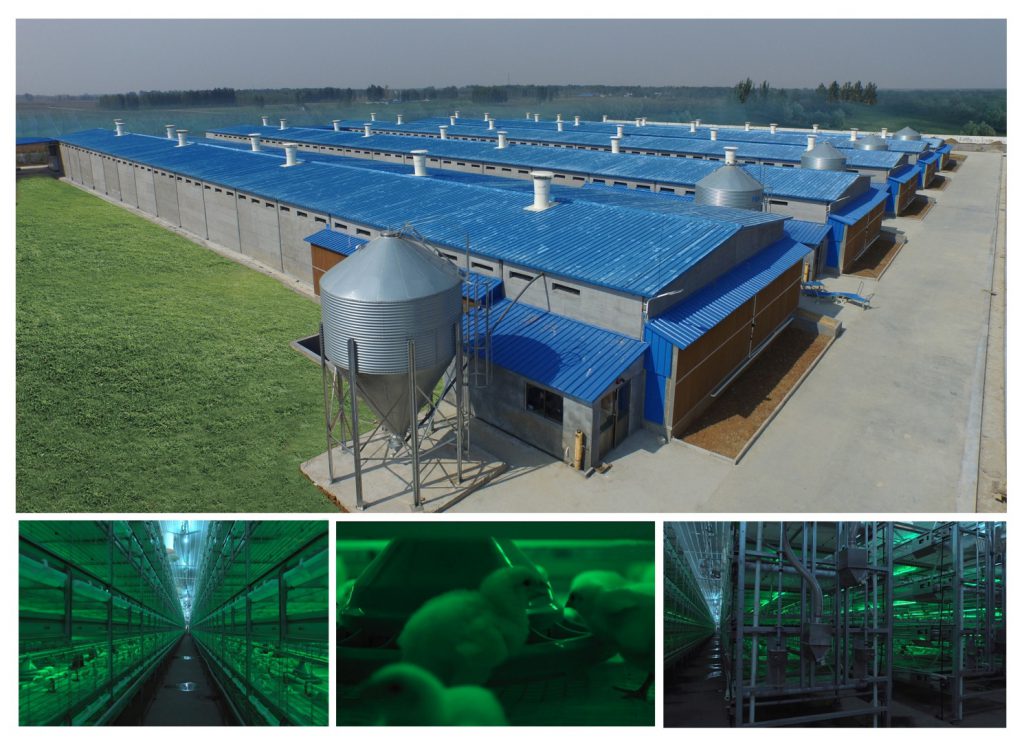

Steel structure chicken photo:

Steel poultry farm building will supply

For your ease and comfort, we will pre-design your building according your demand for fast and efficient installation on your site.

The interior steel frame is made to order, all sizes exactly cut, all holes pre-drilled and all nuts and bolts supplied. Upon correct installation following the guidelines and shop drawing we supplied you do not need cut or weld anything. Just bolt together.

All coverage panels are cut to size, gable ends already cut with the roof angle. All you need to do is slide all the parts together, fit some anchoring screws and bolts and your structure is complete.

Length of structure and quantities vary according to length of structure ordered. (Refer to your quote and invoice for exact quantities)

Your steel poultry farm kit is supplied with the following

1)All Steel Frame parts with prefabricated. (hole,weld,surface treatment etc)

2)All the Roof and Wall Panels already cut to size for your size structure.

3)Completely window and door with hinge,handle etc hardware

4)Bolts, Screws and pop-rivets needed to secure your structure.

5)flashing and Silicone to further help insulate your structure.

6)Other Accessories you have choose: gutter,water spout,ventilation fitting,stairs etc

7)Other internal simple equipment:LED light,shelf racks etc

Poultry farm chicken broiler house

Different countries have distinct climate, market and habits requirements. Generally the width of broiler house is 12m-16m, length is less than 150m, height is 2.1m-3m(for free range) or 2.5m-4.5m(in A type cage or H type)

Our steel structure design poultry farm can be built with different construction methods, close type(sandwich panel for wall and roof, also you can choose the ceiling type) and open type(sandwich panel or steel sheet &aluminum bubble foil for roof, no wall or wire mesh & curtain for wall).

Also you can give us your thoughts, we will help you to realize it.

Steel structure chicken farm drawing:

Normally chicken poultry farm housing can build in two type: Open chicken farm house and Closed chicken farm house

Whether it is an open house or a closed house, there are two forms of flat raising feeding ( yard-housing chicken )and cage raising feeding (cage-housing chicken.)

Flat raising feeding chicken house have two kinds : ground raising and high-level mesh raising

Cage raising feeding chicken house have two kinds: overlapping cages( H shape chicken cage )and stepped cages(A shape chicken cage).

Recommended chicken farm size

Broiler floor raising poultry farm

| No. | Model | Size(m) | Birds/ house | Feeding lines | Drinking lines |

| A | FR-12012 | 120X12 | 21000 | 3 | 4 |

| B | FR-12015 | 120X15 | 28000 | 4 | 5 |

| C | FR-9618 | 96X18 | 30000 | 5 | 6 |

Layer cage poultry farm

| Model | Ties | Length/ cage (mm) | Width/ cage (mm) | Height/ cage (mm) | Area/ bird (cm) | Capacity/ cage | Capacity/ set |

| LC-4288 | 4 | 2400 | 600 | 430 | 400 | 9 | 288 |

| LC-8576 | 8 | 2400 | 600 | 430 | 400 | 9 | 576 |

| LC-3150 | 3 | 2150 | 500 | 430 | 430 | 5 | 150 |

| LC-4200 | 4 | 2150 | 500 | 430 | 430 | 5 | 200 |

Broiler cage poultry farm

| Pan feeding cage | Ties | Size(mm) | Area/ unit (cm2) | Tier height (mm) | Total cage height (mm) | Capacity |

| BC-4420 | 4 | 1800X 3000X 460 | 54000 | 770 | 3650 | 105x4 =420 |

How to order a chicken farm from us

1.Project location?

2. Load of your building.

Wind speed(KM/H) / Snow load (KG/M2) if have / Earthquake load if have

3. Size: width x Length x Eave height ?(if do not have the building size please go to question 7 directly)

4.roof and wall coverage?

5.cool pad , fan, manual door, gate size and quantity etc?

6. Surface treatment : Paint or hot dip galvanize

The following question if for clients who do not know the exactly size of the building size:

7.How many chicken do you want to feeding?

8.free range or cage raising?

9.open or closed environmental control chicken house?

Generally configuration for a chicken house farm:

| Company Name | Qingdao Steel Building Co.,Ltd |

| Application (use) | chicken farm house, poultry farm house, broiler house, breeder house, chicken house, poultry house, broiler farm housing steel structure chicken house, steel structure poultry house, steel structure broiler house, steel structure breeder house, poultry farm, chicken farm house, automatic poultry broiler house, chicken farm, chicken farm building, |

| Building type | Opening --Suitable for areas where the climate is warm and not hot windowed, --Natural wind, when the weather is too hot, mechanical ventilation and water curtains to cool down Closed, (Environmental control) --Suitable for any climate |

| Chicken type | Breeder, egg layer hen, broiler etc |

| breeding type | Flat chicken house, Cage chicken house, Free-range chicken house |

| Grade | Q345(S355JR)or Q235(S235JR) steel or as request |

| Clear span: (width) | 3~25m without middle column popular width: 9m, 10m, 12m, 14m, 15m |

| Height | 2~6m popular height 2.4m for flat chicken house, 5m for cage chicken house |

| Popular bay (column distance) | 3m or 6m |

| Length | as your requirement popular length 30~120m |

Optionalconfiguration choose for an economic chicken house building:

| Column & Rafter | H beam use life 30 year 50 year |

| square tube use life 20 year | |

| C section use life 5-15year | |

| X brace | round steel bar, angle steel or as request |

| Purlin | C purlin, Z purlin, thickness2.0mm, 2.2mm, 2.5mm, 3.0mm |

| Wall & Roof | single corrugated steel sheet (0.3~0.8mm) |

| EPS, Rockwool, PU panel, glass fiber site sandwich panel | |

| (Thickness:50mm, 75mm, 100mm, 150mm, 200mm) | |

| popular insulation: EPS and glass fiber | |

| Gate | Electric roller shutter door |

| sandwich panel Sliding door | |

| Exit Door | Plastic steel swing door |

| Aluminum alloy swing door | |

| steel swing door | |

| Window | Plastic steel sliding window |

| Aluminum alloy sliding window | |

| Surface | Shot blasting with anti rust paint |

| hot dip galvanize | |

| Certificate | ISO99001, CE EN1090 EXC2 , IWE etc |

| Quality Control | The third party , SGS, ASIA INSPECTION all accept |

| Other accessories | fan, vent, ventilation fitting, |

| cooling pad, curtain, | |

| mesh against bird or mouse, | |

| flash trimming cover, anchor bolt, self tapping screw etc | |

| water line, feed line etc Equipment | supply by others or introduce supplier for you |

| Package | main steel frame load in 40'OT, roof and wall panel load in 40'HQ! |

- LAST: Metal Farm Barn Building

- NEXT: Chicken Farm Building